Introduction to Pocket Hole Joinery

Pocket hole joinery is a woodworking technique that has gained popularity for its simplicity and effectiveness. This method involves creating a hole at an angle in one board, allowing for a screw to enter from the side of the connected piece without the need for extensive preparation or visible fasteners. Unlike traditional joinery techniques, such as dovetails or mortise and tenon joints, pocket hole joinery emphasizes speed and ease of assembly, making it particularly appealing for both DIY enthusiasts and professional woodworkers alike.

To successfully execute pocket hole joinery, several key tools are necessary. The most critical of these is the pocket hole jig, which guides the drill to create the angled holes precisely. Pocket hole jigs come in various designs, ranging from simple manual models to more advanced, adjustable commercially available options. Alongside the jigs, the use of specialized pocket hole screws is essential. These screws are designed with a flat head that provides a strong grip in the piloted hole, ensuring a secure connection between the joined pieces.

The advantages of pocket hole joinery are manifold. Primarily, it significantly reduces assembly time, as the creation of joints is straightforward and requires minimal setup. Additionally, the angle of the pocket holes allows for strong, durable connections without visible screw heads, resulting in a clean, finished look for furniture and cabinetry. Historically, pocket hole joinery has evolved from a relatively obscure method to a mainstream technique, particularly since its endorsement by leading woodworking brands and tutorials. Its rise in popularity can be attributed to the growing interest in DIY projects and home improvement, cementing pocket hole joinery as a go-to technique for many woodworkers looking for both quality and efficiency in their craft.

Situations Where Pocket Hole Joinery Shines

Pocket hole joinery is a favored technique in woodworking, particularly in scenarios where strength, speed, and aesthetic appeal are paramount. One of the most advantageous applications of pocket hole joinery is in frame and panel construction. This method allows woodworkers to create robust frames that can effectively support large panels without compromising stability. The angled screws utilized in pocket hole joinery provide superior holding power, ensuring that the finished product withstands the test of time.

Another scenario where pocket hole joinery excels is in assembling furniture projects. Whether crafting tables, cabinets, or chairs, this joinery technique simplifies the process while enhancing durability. Many craftsmen appreciate the ability to create strong joints without the need for complex aligning systems. Additionally, the hidden nature of the pocket holes allows for a clean finish, making it an ideal choice for visible surfaces. To ensure optimal results, it is advisable to select high-quality screws designed for pocket hole use, as these are specifically engineered to maintain tight joins.

Joining face frames is another situation that greatly benefits from pocket hole joinery. When constructing face frames for cabinetry, the pocket hole method offers a streamlined approach to joining multiple pieces of wood. In this application, the strength of the connection is critical, especially since face frames often bear the weight of doors and drawers. By utilizing pocket holes, woodworkers can easily create strong, precise joints that not only support functionality but also enhance visual appeal.

For those aiming to achieve the best results with pocket hole joinery, it is beneficial to pre-drill the holes, ensuring proper alignment and reducing the risk of splitting. Additionally, using clamps during assembly will secure the pieces in place while the screws are driven in, leading to a cleaner, more professional finish. Thus, pocket hole joinery stands out as a practical and effective choice in various woodworking endeavors, providing both strength and style.

Limitations of Pocket Hole Joinery

Pocket hole joinery is a popular technique in woodworking, celebrated for its simplicity and speed. However, it does come with certain limitations that must be considered when deciding on the best joinery method for a project. One significant drawback is the structural strength of pocket hole joints. While they can provide adequate support for many applications, they may not offer the same level of sturdiness as traditional joinery methods, such as mortise and tenon or dovetail joints. In high-stress situations or where durability is critical, relying solely on pocket holes may lead to potential failures.

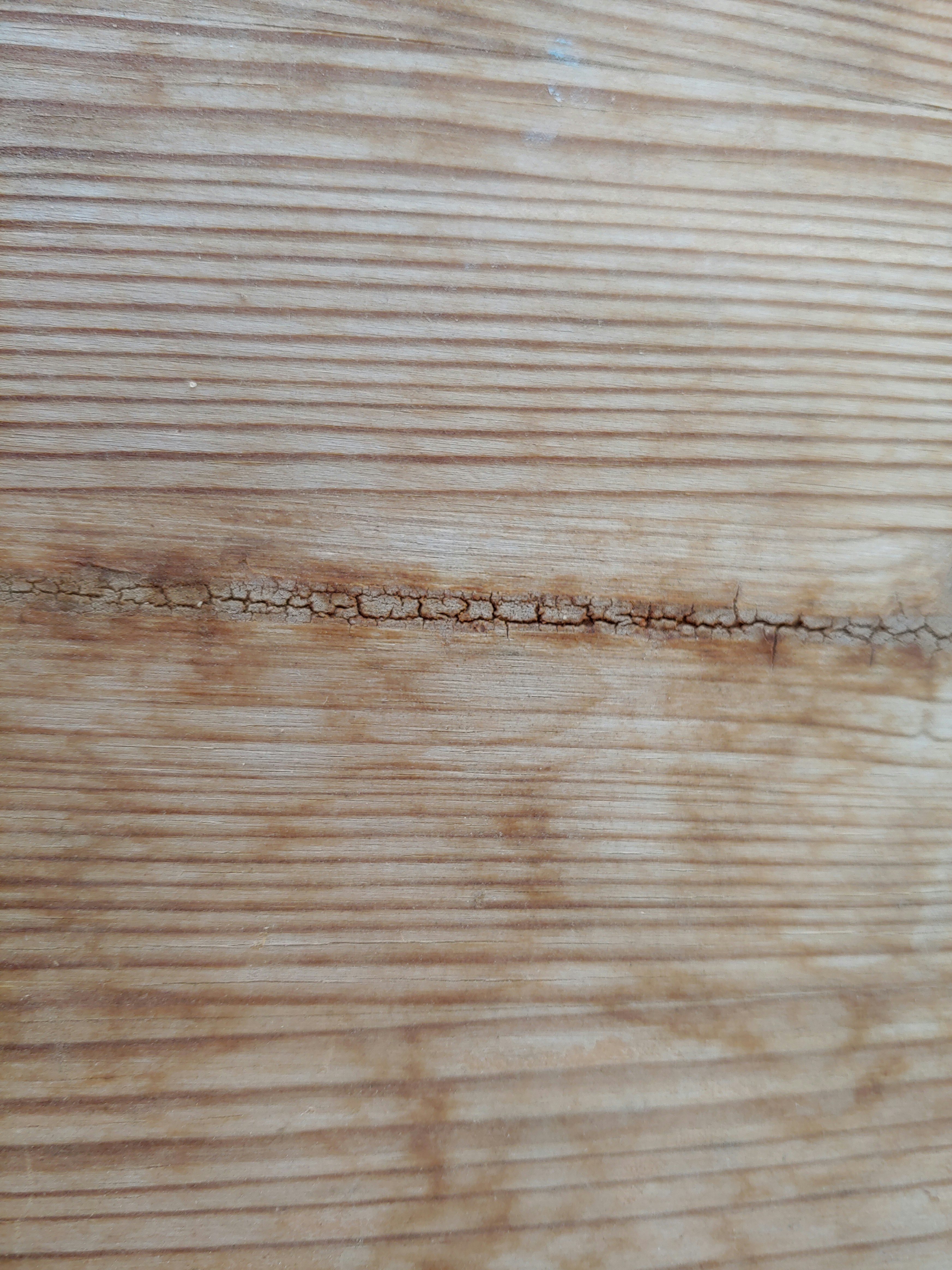

Another limitation is the visibility of pocket holes in finished projects. When creating visible joints, the pocket holes can detract from the aesthetic quality of the piece, particularly in fine furniture making where appearance is paramount. In such cases, traditional joints, which can be hidden or finished seamlessly, may be more appropriate. For instance, a handcrafted dining table meant for display and use might benefit from the elegance of a more traditional joinery approach.

Additionally, certain woodworking projects require high precision and a level of customization that pocket holes cannot reliably fulfill. Applications that demand exact measurements and tight tolerances, such as cabinetry work or ornate designs, often necessitate joinery methods that provide better adaptability. Alternatives, such as dado joints, spline joints, or even lap joints, can be more suitable for these tasks and help ensure both aesthetic and structural integrity.

In conclusion, while pocket hole joinery serves as an efficient solution for various projects, understanding its limitations is essential for making informed choices in woodworking. Evaluating the specific requirements of a project will assist woodworkers in determining when to use pocket holes and when to consider more traditional joinery options for optimal results.

Best Practices for Using Pocket Holes Effectively

Executing pocket hole joinery effectively requires attention to detail and adherence to best practices that enhance the overall quality of the joinery. The first step involves proper jig setup. Ensure that the pocket hole jig is securely clamped to your work surface, providing stability. Adjust the settings based on the thickness of the wood being joined; most jigs come with specific guides for different material dimensions. A well-secured jig helps maintain consistent hole placement, leading to stronger joints.

Choosing the right drill bit is equally important. Use a step drill bit designed for pocket holes, as it creates smooth, angled holes crucial for the joint’s integrity. The bit’s sharpness can significantly influence the quality of the hole; hence, replace blunt bits promptly. For wood selection, opt for dense hardwoods when possible, as they offer better grip for screws, reducing the likelihood of the screws stripping over time.

Alignment techniques also play a pivotal role in pocket hole joinery. It’s essential to align the pieces accurately before tightening the screws. When clamping the two pieces, ensure they are flush against each other. A mismatch can lead to weakened joints; therefore, double-check alignment before fastening. Additionally, if misalignment occurs, re-drill if necessary, or adjust the clamping method to rectify the issue.

Common troubleshooting tips include identifying signs of weak joints, such as excessive movement or gaps. If you encounter stripping, consider using anti-strip screws or pilot holes to enhance grip. Finally, to achieve a polished look, employ finishing techniques that mask the pocket holes, such as wood filler or paint, ensuring the joint lines remain discreet. By following these best practices, readers can attain durable, aesthetically pleasing results in their pocket hole projects.

If you’re interested in purchasing the item you seek, please click the link for additional details: #americanachoice.

https://amzn.to/3SBN3Oy

AFFILIATE DISCLOSURE: I am an affiliate for this company, I am not a paid employee.

I may receive a commission if you click a link on this page and choose to purchase something.

You can rest assured I will only share things I believe in and will be valuable to you.