Understanding Circular Saw Blades

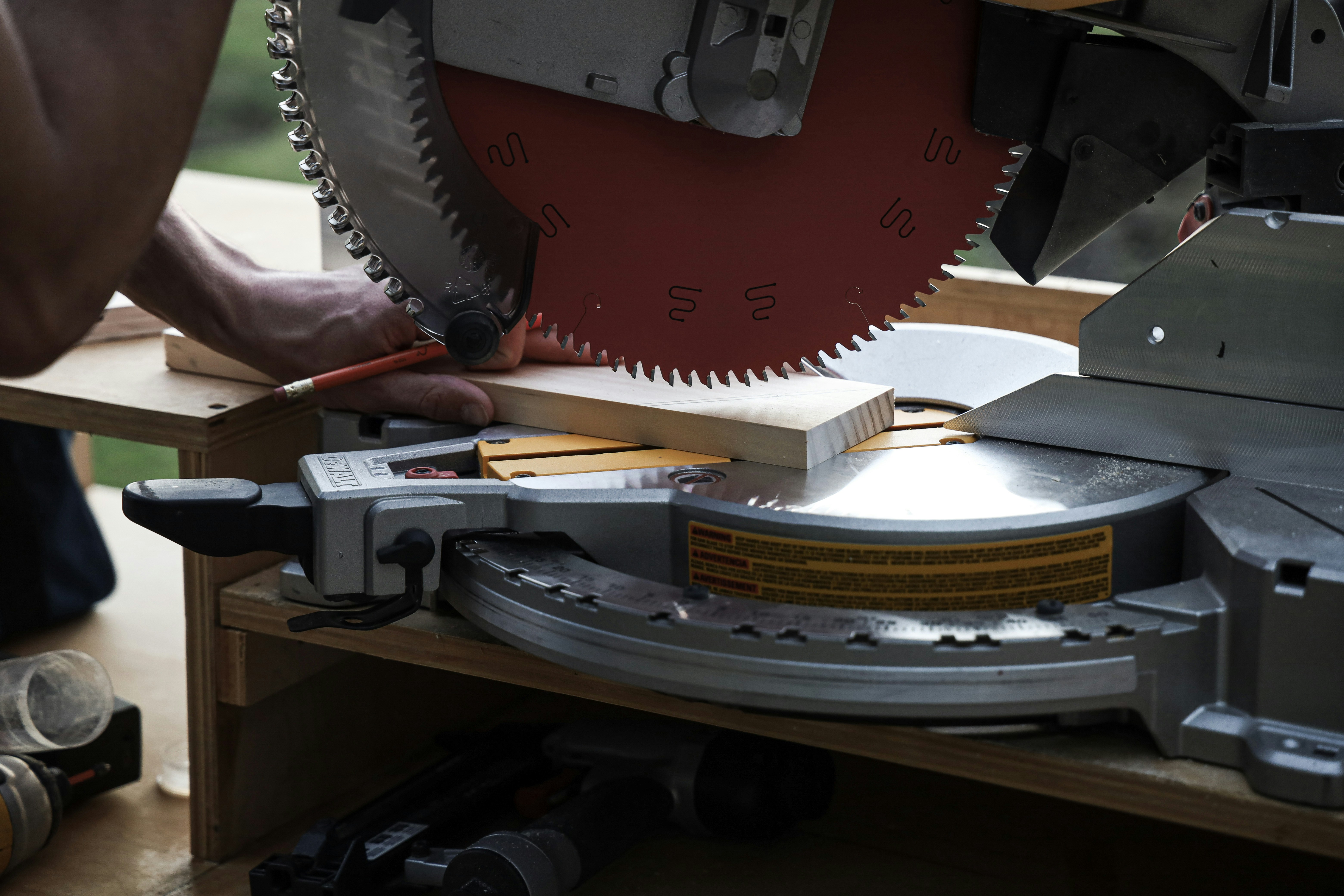

Circular saw blades are essential tools for a variety of cutting applications, and a clear understanding of the different types available can significantly enhance your woodworking or construction projects. Among the many options, high-speed steel (HSS), carbide-tipped, and diamond blades stand out due to their unique construction and distinct applications.

High-speed steel blades are often utilized for their affordability and versatility. They can effectively cut through softer materials but may dull quickly when used on harder substances. In contrast, carbide-tipped blades offer superior durability and longevity, making them suitable for cutting dense hardwoods and engineered materials. The carbide tips create a sharp, long-lasting edge that maintains its performance over extended periods, which is particularly important for professional woodworkers.

For specialized applications, diamond blades are favored, especially in cutting through materials like concrete, ceramics, and masonry. The diamonds embedded along the blade’s edge enable efficient cutting and provide a longer lifespan than traditional wood-cutting blades. Each type of circular saw blade is designed with specific cutting needs in mind, ensuring that users can achieve optimal results based on the chosen material.

Blade size and teeth configuration also play a crucial role in cutting performance. Larger blades can enhance cutting depth, while different teeth configurations influence the quality of the cut. A blade with more teeth produces smoother cuts, which is advantageous for finish work, while blades with fewer teeth are better suited for faster cuts in thicker materials.

By gaining an understanding of these fundamental characteristics of circular saw blades, users can make informed selections tailored to their specific projects, resulting in improved efficiency and reduced cutting errors.

Factors to Consider When Choosing a Blade

Choosing the right circular saw blade is paramount in achieving optimal cutting results while minimizing expenses. Several critical factors come into play when selecting a blade, and these considerations can significantly impact both the quality of the cut and the longevity of the saw. First and foremost, one must evaluate the type of material being cut. Different materials require specific blade designs; for instance, wood typically requires blades with fewer teeth for fast cuts, while laminate and metal demand blades with more teeth for smoother finishes.

Another essential factor is the thickness of the material. Thicker materials necessitate blades with a larger kerf to accommodate the cut, ensuring efficiency and reducing the risk of binding. Additionally, the desired finish quality is vital; if a high-quality, polished edge is required, blades with more teeth and finer grinds should be utilized. Conversely, if speed is prioritized, a blade with fewer teeth may be more appropriate.

Moreover, understanding the RPM (revolutions per minute) is crucial, as different blade types and saw models operate optimally at varying speeds. A mismatch between the saw’s RPM and the blade’s design can lead to poor cutting performance and increased risks of blade damage or operational hazards.

One common pitfall when choosing a blade is making decisions based solely on price, which can lead to long-term costs. A cheaper blade may save money upfront but may not provide the durability required, leading to frequent replacements and inefficient cuts. Therefore, it is essential to weigh the initial cost against the overall performance and longevity of the blade, ensuring a well-informed choice that enhances productivity and reduces waste.

Common Mistakes in Blade Selection and Their Consequences

Selecting the appropriate circular saw blade can significantly impact the efficiency and safety of your cutting tasks. However, many users commit common mistakes that can lead to expensive repercussions. One prevalent mistake is using the wrong tooth count for the material being cut. For instance, a blade with fewer teeth may be suitable for softer materials, like plywood, while a higher tooth count is preferred for hardwood or laminates, as it offers a smoother finish. Employing an incorrect tooth count can result in rough cuts, splintering, and increased stress on the motor, ultimately leading to premature wear on the saw.

Another error often overlooked is the failure to consider material compatibility. Each blade is designed for specific materials, be it wood, metal, or masonry. Selecting a blade that is not intended for the intended material can produce various complications, including a decrease in cutting performance and the potential for the blade to become damaged or warped. This oversight not only hampers productivity but may also pose safety hazards, such as kickback or blade breakage during operation.

Brand reputation is another critical factor that is frequently disregarded. Opting for a less reputable or untested brand in circular saw blades can compromise safety and effectiveness. Established brands often guarantee quality through rigorous testing and provide consistent performance, while off-brand blades may result in inconsistent cuts or premature failure, ultimately threatening the user’s safety.

By identifying these common mistakes—such as incorrect tooth count, material incompatibility, and overlooking brand quality—users can avoid the potential risks and ensure a smoother, safer cutting experience. Proper blade selection not only enhances performance but also minimizes the likelihood of costly errors in the long run.

Maintenance Tips for Prolonging Blade Life

Maintaining circular saw blades is crucial for extending their lifespan and enhancing cutting efficiency. Proper care not only ensures optimal performance during usage but also minimizes the frequency of replacements, thereby reducing costs associated with blade procurement. A fundamental aspect of maintenance is regular cleaning, which prevents the buildup of sawdust, resin, and other materials that can hinder performance. After each use, it’s advisable to wipe the blade with a cloth or brush to remove debris. For more thorough cleaning, soaked solutions or specialized cleaners can be applied occasionally, ensuring the blade remains in pristine condition.

Storage methods are equally important when it comes to maintaining circular saw blades. Blades should be stored in a dry, protected environment, ideally in a designated case or on a rack that prevents them from coming into contact with other hard surfaces. This practice minimizes the risk of blade damage, such as nicks or bends, which can occur when blades are stored loosely. Additionally, storing blades in a vertical position can help in preserving their sharpness and overall integrity.

Understanding when to replace or sharpen a blade is another essential maintenance tip. A circular saw blade should be replaced when it shows signs of significant wear, such as visible teeth damage or a noticeable decrease in cutting efficiency. However, if the blade remains structurally sound but dull, sharpening is typically the preferred option. This process can restore the blade to its original cutting capabilities without the need for a complete replacement. Regular maintenance practices, including cleaning and appropriate storage, combined with timely blade replacement or sharpening, significantly enhance the longevity and functionality of circular saw blades. By adopting these methods, users can ensure their blades perform optimally, prevent accidents, and ultimately save money in the long run.

If you’re interested in purchasing the item you seek, please click the link for additional details: #americanachoice.

https://amzn.to/3SBN3Oy

AFFILIATE DISCLOSURE: I am an affiliate for this company, I am not a paid employee.

I may receive a commission if you click a link on this page and choose to purchase something.

You can rest assured I will only share things I believe in and will be valuable to you.